Blog

22

MayIXYS UK Westcode have today introduced the maximal true current rating press-pack IGBT available that is set to break new ground in power handling capability of an individual device. The latest symmetric blocking device with a incessant DC rating of 2.8Kv has a unprecedented DC current of 6000A. The latest device has been aided by IXYS UK’s comprehensive expertise in making and understanding the principles of very big press-pack IGBTs with more than one parallel die. The recently developed 4.5Kv devices include vindicated SPT plus die technology and are built using 52 parallel connected IGBT die, 10 more than the biggest established part with a current rating of 2400A at the same 4.5Kv blocking voltage. Every die is 14.3mm square with an active area of nearly one centimetre squared. The latest device encapsulated in completely sealed 26mm thick with a 132mm electrode diameter, bigger than the traditional 2400A device, but keep up the similar 170mm in-total diameter as the 42 die design; this provides an effective 25% more current rating in the same package. The sturdy internal development is without bond with the single die straight away pressure contacted through metallic pressure plates to the outside copper electrodes. The outright bond free contact confirms maximum reliability and unparalleled thermal cycling properties, far exceeding those of a conventionally packaged plastic package module. In particular, the short circuit failure mode makes these devices the obvious choice for applications requiring series operation, such is the case in utilities, HVDC and very large medium voltage drives. The unrivalled current rating can also reduce the number of parallel paths required in very high current applications in the multi megawatts range. Generally, these devices are well suited to harsh environments and where maintenance access is difficult such as off-shore marine and wind. The hermetic structure and high rupture resistance are properties which are particularly relevant in harsh environments where explosive failure and plasma leak are unacceptable, such as mining, gas and oil instillation. The package design is based on IXYS UK’s proven technology, with the same conveniences of enhanced rupture capability, resisting more than ten times the short circuit energy of a conventional plastic packaged module device and the additional advantage that the device is virtually guaranteed to fail to a stable short circuit. These unique properties make the new device an ideal solution where high reliability, maximum power density and predictable failure are important. To facilitate the application of this new higher rated press-pack IGBT, IXYS UK Westcode has also launched a new complementary diode in its range of very high di/dt HP Sonic FRDs. This new diode is constructed using a new die bonding technology to maximize reliableness. Packaged in an 85mm electrode 26mm thick package the diode is pressure compatible with the press-pack IGBT so it can be mounted in the same series string for compact three level inverter configurations. Part number designations for this reverse conduction press-pack IGBTs is T2960BB45E & the compatible HP Sonic FRD is part number E3000TC45E. Typical applications for these devices include: utilities and HVDC applications such as, flexible AC transition systems, HVDC transition, Statcoms, VSC SVC etc; medium voltage AC drives for harsh environments and ultra-high power, such as mining, marine and off shore g, gas and oil installations; renewable energy for wind turbines, hydro generation, wave generation and solar; plus, any application where high power density and reliableness is necessary. Read more >>

26

May

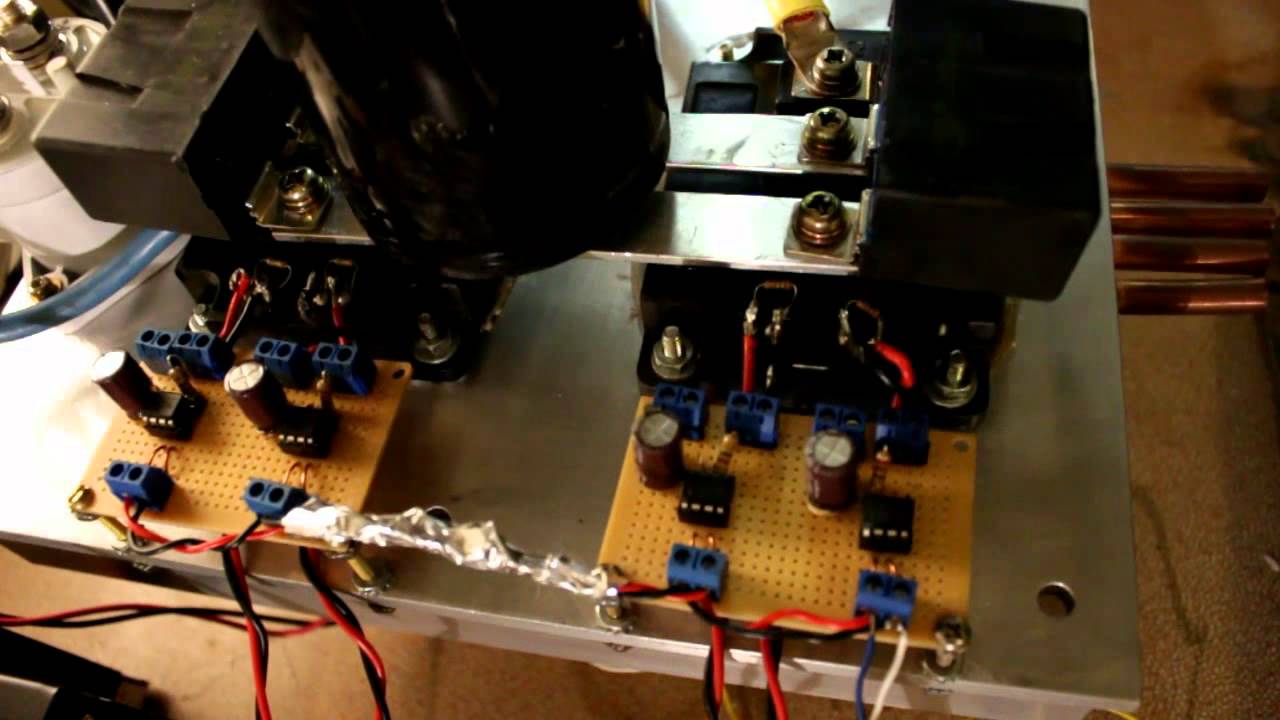

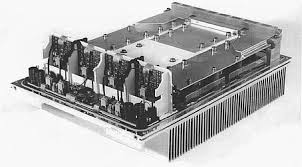

Prior to the evolution of the IGBT, power electronics engineers had two kinds of devices for fast and higher frequency switching – the Bipolar Junction Transistor (BJT) and the Metal Oxide Field Effect Transistor (MOSFET). Both could switch at higher frequencies than Thyristors (or SCRs). However, either had some limits. MOSFETS provided high switching speeds, yet high voltage and high current plans were comparatively steep, while BJTs were available in high voltage and high current designs, however offered lower exchanging speeds to some extent. Insulated Gate Bipolar Transistors (IGBTs) are switching devices with three terminals, which could successfully be deliberated to consist of an insulated gate N-channel MOSFET associated with a PNP Bipolar Junction Transistor. The IGBT unites the high voltage and current capacity of the BJT with the voltage control attributes of a MOSFET which allow higher frequency switching. The IGBT has three connections, Emitter, Gate and Collector. The conduction path is through the Collector and Emitter. Identical to a Thyristor, the IGBT allows controlled current to go through when a signal is recognized at the Gate. A thyristor is “current” and switches “ON” when a pulse is given to the Gate. The IGBT is controlled by voltage, allowing conduction when a positive voltage is there on the Gate, and only switching “OFF” when the voltage is reduced to zero, or ideally, driven negative. The output current and voltage attributes are same to the BJT, but driving the device using the voltage control of the MOSFET facilitates the switching. Another significant convenience over normal MOSFET operation is lower on-state voltage. The resistance provided by the conducting channel in an IGBT is too much smaller, leading to much higher current ratings than for an similar power MOSFET. IGBTs are the best choice for switching current on and off in high power applications. IGBTs are made for use in power applications above 1kW, the point at which BJTs and standard MOSFETs reach their limits, switching at frequencies between 1kHz and 20 kHz. Low voltage applications (<600V) tend to be high volume consumer oriented, for example to control motor drives for washing machines. Key applications include automotive (electric vehicles), rail traction equipment and industrial motor drives, where operating voltages are higher – 1200V or 1700V are typical of the standard ranges available. In numerous applications, rather than using more than one discrete devices, IGBTs are associated into modules, to provide full circuits for particular power control. Read more >>

29

May

Después de evolucionar lado a lado en las últimas tres décadas, los transistores bipolares de puerta aislada (IGBTs) y MOSFET dominan ahora el mercado de semiconductores de potencia en aplicaciones como unidades de motor, fuentes de alimentación ininterrumpida (UPS) e inversores solares. Entonces, ¿dónde hacer IGBTs hacer el mejor ajuste, y cuándo tiene sentido de diseño mejor para ir con un MOSFET? Estructuras y principios básicos El IGBT es un dispositivo semiconductor que combina las características de salida de un transistor bipolar y las características de accionamiento de puerta de un MOSFET. Por lo tanto, el IGBT es un dispositivo portador de minorías con alta impedancia de entrada y alta capacidad de transporte de corriente. En comparación con los MOSFETs, los IGBT también son más adecuados para escalar en capacidad de manejo de corriente a niveles de voltaje más altos debido a sus características de salida bipolares. Read more >>

29

May

IXYS Corporation, a leading maker of power semiconductors and ICs for power management, energy efficiency and motor control applications announced the 1700V and 2500V XPT™ IGBTs for power management applications. The current ratings of the new devices range from 26A to 178A and these are perfect for high-voltage (“HV”), high-speed power conversion applications. Devices which are packed together with anti-parallel fast diodes are also available. IXYS has an enriched history of presenting cutting edge, state-of-the-art IGBTs and had introduced the HV IGBT outline and applications in power management particularly in the transportation, medical and manufacturing markets. Designed by utilizing the patented IXYS Extreme-Light Punch-Through (XPT™) technology and the leading edge IGBT processes, these latest devices characteristics such as lessened thermal resistance, little tail current, little energy loss, and fast switching capacity. Also, the positive temperature coefficient of their on-state voltage gets credit, the latest high-voltage IGBTs can be used in parallel, which provides cost-efficient solutions compared to series-connected, lower-voltage device ones. This therefore results in diminishing in the related gate drive circuitry, simplicity in design, and advancement in the reliableness of the overall system. The non-compulsory co-packed fast recovery diodes have less reverse recovery time and are designed to generate smooth switching waveforms and notably lower electromagnetic interference (EMI). A significant number of high-voltage (“HV”), high-speed power management applications that can get advantage from using these IGBTs. Among them are HV converters, inverters, power pulse circuits, laser and X-ray generators, HV power supplies, HV test equipment, capacitor discharge circuits, medical switching applications, HV circuit protection, and HV AC switches. The new XPT™ IGBTs are found in the following international standard size packages: SOT-227, TO-247, PLUS247, ISOPLUS i5-Pak™, TO-247HV, TO-247PLUS-HV, and TO-268HV. The latter three have increased creepage distances between leads, making them sturdy against provoked voltages. Some example part numbers include IXYH24N170C, IXYN30N170CV1, IXYH30N170C, and IXYH25N250CHV, with collector current ratings of 58A, 88A, 108A, and 95A, respectively. Read more >>

29

May

Actualmente el mercado enfrenta una modernización inevitable esto incluye los modulos IGBT que empiezan a reemplazar aparatos rupestres y antiguos con la gran oleada tecnológica y ademas SIMPLEZA que los IGBT tienen, en este articulo exploraremos dos grandes factores: Mercado Global de IGBT y Tiristores: Factores de Crecimiento Debido a la tecnología desarrollada y la introducción de redes inteligentes en el sector de la energía, se prevé que el mercado mundial de IGBT y tiristores aumentará en un futuro próximo. Sin embargo, el aumento de la población y la demanda de una enorme fuente de energía se espera que realce el crecimiento del mercado. IGBT y tiristor se utilizan como fuentes de alimentación, controladores e inversores en aplicaciones de electrónica de potencia para satisfacer la creciente demanda de dispositivos de conmutación de estado sólido. Se espera que el número creciente de familias e infraestructura nucleares alimente la demanda del mercado en el futuro. IGBT y tiristores acomodan varias ventajas tales como menos tiempos de conmutación de MOSFET y pérdidas mínimas de conmutación para satisfacer las demandas actuales de electricidad en el futuro. Mercado Global de IGBT y Tiristores: Segmentación El mercado mundial de IGBT y tiristores puede ser segmentado en base a la aplicación como sistema de transmisión de CA flexible (FACTS) y HVDC. De los cuales, la aplicación de sistema de transmisión de CA flexible (FACTS) es el segmento líder en el mercado, ya que se utiliza para la gestión de la congestión, estabilización de voltaje, estabilización de frecuencia; Mantener el control de flujo de potencia y estabilidad, y otros. Otros segmento de aplicación es sub-segmentado como EV / HEV, energía renovable, regulador de nivel de líquido, transporte, regulador de luz, control de presión, controles de motor, etc. Read more >>

29

May

Wolfspeed introduces SiC technology to outdoor systems in transportation and renewable energy. Wolfspeed has stretched its SiC power devices with the launch at PCIM 2017 of the industry’s inaugural power module that overcomes the tough environment qualification test for concurrent high-humidity, high-temperature and high-voltage situations. This reliableness benchmark allows system designers to utilize this device in outdoor applications such as transportation, wind, solar and other renewables where ultimate environmental conditions have traditionally challenged secure device operation. The latest all-SiC module, rated for 300 A and 1.2 kV blocking, was strained in an 85% relative humidity, 85 degree celsius ambient while biased at 80% of rated voltage (960V). Accomplishment in tough situation testing under bias provides further confidence in the overall robustness of SiC device technology for all applications. “SiC components enable the design of compact, lightweight, low–loss converters required for railway transport applications,” said Michel Piton, semiconductor master expert at Alstom, a leading global supplier of systems, equipments and services for the railway market. “Achieving March 2017 the benchmark for temperature and humidity under high bias voltage is a key milestone for SiC devices in its adoption into our demanding market.” Powered by new Wolfspeed MOSFETs (CPM2-1200-0025A) and Gen5 Schottky diodes that also pass the tough environment test at the die level, the latest module retains the low 4.2 mΩ on-resistance and more than five times lower switching losses than similarly rated, latest generation IGBT modules. Module construction uses high thermal conductivity aluminum nitride substrates and optimised assembly methods to meet industry thermal and power cycling requirements. “This device is yet another industry-first driven by Wolfspeed,” said John Palmour, Wolfspeed’s chief technology officer. “The latest 1200V module demonstrates our commitment to enabling markets and applications by meeting the anticipated system requirements for 2020 and beyond.” Available under part number WAS300M12BM2, the latest module can be driven using existing Wolfspeed gate drivers for 62mm modules. Read more >>

30

MayAunque las generaciones mas modernas de los IGBT suelen tener mas capacidad de aguante y una incidencia a incidentes de apagado casi nula vale la pena saber cuales son las caracteristicas a evitar y como reconocer cuando sucede una de estas fallas para asi prolongar de manera significativa la vida de nuestros IGBT o MOSFETS y cuando no dan para mas, saber cuando cambiarlos. Sobrecarga Esencialmente, el comportamiento de encendido y conmutación de IGBTs y MOSFETs bajo sobrecarga no difiere de la "operación estándar" bajo condiciones nominales. Con el fin de no sobrepasar la temperatura de unión máxima y para garantizar un funcionamiento seguro, el rango de sobrecarga tiene que ser restringido, ya que una mayor corriente de carga puede causar una mayor disipación de energía en el dispositivo o la destrucción de componentes tales como diodos debidos a efectos de modo de fallo dinámico. Cortocircuito Esencialmente, IGBT y MOSFET son a prueba de cortocircuitos, es decir, pueden ser sometidos a cortocircuitos bajo ciertas condiciones dadas y desactivarlos activamente sin dañar los semiconductores de potencia. Read more >>

30

May

Dada la amplia disponibilidad de IGBTs y MOSFETs de potencia de alto voltaje con clasificaciones de voltaje de ruptura de 500 a 800 V, los diseñadores suelen enfrentarse al reto de seleccionar un IGBT o MOSFET para una aplicación dada y un conjunto de condiciones operativas. En el caso de accionamientos de motor de velocidad variable trifásicos en el rango de potencias nominales de 300 W a 5 kW, utilizando una tensión de bus cc en el rango de 300 a 400 V y típicamente implementado mediante una topología de seis interruptores, Los IGBT de 600 a 650 V (co-empaquetados con un diodo de recuperación rápida anti-paralelo) han sido tradicionalmente el dispositivo preferido desde una perspectiva de rendimiento global. Sin embargo, con la disponibilidad de alta velocidad de conmutación, RDS bajo (on) y diodos de cuerpo de recuperación relativamente rápidos de 500 a 650 V, se plantea la cuestión de si es hora de que el IGBT ceda el MOSFET Read more >>

31

May

El IGBT tiene la ventaja sobre el MOSFET a mayores frecuencias de conmutación. Pero a frecuencias de conmutación más bajas, el MOSFET tiene la pérdida global más baja y la temperatura de unión de funcionamiento más baja. (El IGBT y MOSFETs seleccionados tienen aproximadamente los mismos tamaños de matriz y impedancias térmicas.) Esto es de alguna manera contraria a la sabiduría convencional donde a menudo se argumenta que los MOSFET tienen un mejor desempeño en frecuencias de conmutación más altas. Sin embargo, estos resultados indican lo contrario y pueden atribuirse principalmente debido al componente de pérdida de recuperación de diodos significativamente más bajo del IGBT + FRD (diodo de recuperación rápida) y la mejora significativa en minimizar el comportamiento de corriente de cola del IGBT. La menor pérdida de conmutación del IGBT + FRD debido a un componente de pérdida de recuperación de diodo significativamente menor le da la ventaja sobre el MOSFET a 20 kHz (una frecuencia de conmutación relativamente alta para esta aplicación). Además, la pérdida de conmutación del MOSFET se puede reducir significativamente mediante el uso de un controlador de puerta con una mayor capacidad de fuente y corriente de hundimiento (por ejemplo, un controlador de fuente de alimentación 2-A / corriente de hundimiento). Como resultado, las pérdidas totales de MOSFET se reducirían y permitirían al MOSFET cerrar la brecha entre éste y el IGBT. El dv / dt superior resultante, sin embargo, podría causar efectos indeseables tales como sonidos de alta frecuencia y un mayor nivel de EMI irradiado. Curiosamente, a frecuencias de conmutación más bajas donde domina la pérdida de conducción, el MOSFET se beneficia debido a la ausencia de una "rodilla" en sus características de avance, junto con un RDS relativamente bajo (on). Mientras que el IGBT sigue siendo el mejor dispositivo para seleccionar en este ejemplo de aplicación, la disponibilidad de significativamente menor RDS (on) MOSFET junto con un mejor comportamiento de recuperación de diodos y un conductor fuerte puerta podría comenzar a inclinación de la balanza hacia el MOSFET. En ese caso, llegaría entonces a una relación coste / rendimiento ("$ / Amp") con el IGBT probablemente teniendo el borde debido a una densidad de corriente mucho superior (para un tamaño de dado dado). Los IGBTs y MOSFETs similares están a menudo disponibles para una aplicación dada. Es útil comprender claramente las ventajas y limitaciones de ambos dispositivos y elegir uno que mejor se adapte a los requisitos en términos de rendimiento general y costo. Si bien esto no es un esfuerzo fácil, una mayor familiaridad con estos dispositivos de energía resultará beneficioso en la navegación de estas decisiones complejas. Read more >>

01

Jun

Informe Mercado de Semiconductores Automotrices Acelere la Demanda de Componentes de Energía como IGBT y MOSFET parte 1

En este informe ofrecemos una evaluación completa del mercado. a través de profundas ideas cualitativas, datos históricos y proyecciones verificables sobre el tamaño del mercado. Las proyecciones presentadas en el informe se han derivado utilizando metodologías y suposiciones de investigación probadas. Al hacerlo, el informe de investigación sirve como un repositorio de análisis e información para cada faceta del mercado, incluyendo pero no limitado a: mercados regionales, tecnología, tipos y aplicaciones. Aumentar los sistemas de seguridad, no sólo la seguridad pasiva, p. (ABS), control electrónico de estabilidad (ECS), detección de puntos ciegos (BSD), control adaptativo de crucero (ACC) y asistencia de cambio de carril (LCA), entre otros. . Todas estas funciones inteligentes mencionadas anteriormente requieren un dispositivo semiconductor para realizar su función. La función principal de un semiconductor es conducir la electricidad fácilmente en una dirección entre otras funciones más específicas. Las regulaciones sobre seguridad y emisión impulsarán el mercado de los componentes y dispositivos conectados en el vehículo para asegurar el monitoreo y la notificación de la emisión de vehículos cumpliendo con las regulaciones establecidas por el gobierno. Read more >>

02

Jun

Informe Mercado de Semiconductores Automotrices Acelere la Demanda de Componentes de Energía como IGBT y MOSFET parte 2

Las regulaciones sobre seguridad y emisión impulsarán el mercado de los componentes y dispositivos conectados en el vehículo para asegurar el monitoreo y la notificación de la emisión de vehículos cumpliendo con las regulaciones establecidas por el gobierno. Requieren semiconductores cada vez más potentes para garantizar que el rendimiento de los vehículos está en conformidad. Por lo tanto, la razón anterior a su vez está ayudando al mercado de semiconductores automotrices para crecer durante el período previsto de 2016-2024. Además, los estándares de vehículos como el programa de evaluación de vehículos nuevos (NCAP), que otorga calificaciones de seguridad a los nuevos vehículos fabricados como estrellas, están impulsando a los fabricantes de automóviles a proporcionar más y más componentes electrónicos para proporcionar más seguridad y sistemas de seguridad para el vehículo. Obtener el nivel más alto de cinco estrellas puede actuar como un punto de venta fuerte para los vehículos. Su logro se basa en complejos y sofisticados sistemas de conducción asistida que requieren un contenido significativo de semiconductores para que estos sistemas funcionen. Read more >>

07

Jun

Infineon Technologies AG (FSE: IFX / OTCQX: IFNNY) expande su cartera de productos de modulos IGBT ofreciendo con un discreto de 1200 V hasta 75 A. Los dispositivos están co-embalados con un diodo de máxima clasificación en un paquete TO-247PLUS. Los nuevos paquetes TO-247PLUS sirven a la creciente demanda de mayor densidad de potencia y mayor eficiencia en paquetes discretos. Las aplicaciones típicas con una tensión de bloqueo de 1200 V que requieren una alta densidad de potencia son unidades, fuentes de alimentación fotovoltaicas e ininterrumpidas (SAI). Otras aplicaciones incluyen sistemas de carga de baterías y almacenamiento de energía. En comparación con un paquete TO-247-3, el nuevo paquete TO-247PLUS puede proporcionar una clasificación de corriente doble. Debido a la eliminación del orificio de tornillo del paquete estándar TO-247, el paquete PLUS tiene un área de marco de plomo más grande y por lo tanto puede acomodar chips IGBT más grandes. Ahora, por primera vez, se dispone de hasta 75 A de 1200 V con IGBTs con la misma pequeña huella. El marco de plomo más grande proporciona una menor resistencia térmica del TO-247PLUS, dando lugar a una capacidad mejorada de disipación de calor. Para los diseñadores que buscan mejorar las pérdidas de conmutación, el paquete delTO-247PLUS 4pin cuenta con un pin de fuente de emisor Kelvin extra. Esto permite un bucle de control por la puerta del emisor a su vez lainductancia es ultrabaja y reduce las pérdidas totales de conmutación E (ts) en más del 20% Los IGBTs clasificados como 1200 V como el TO-247PLUS de 3 y 4 paquetes se pueden utilizar para aumentar la densidad de potencia del sistema. Además, pueden reducir el número de dispositivos de alimentación utilizados en paralelo, aumentar la eficiencia del sistema o mejorar las condiciones térmicas del sistema. Read more >>

08

Jun

TRENCHSTOP™ Performance IGBT improves energy efficiency for home appliance and industrial applications

On last April 28th, Infineon Technologies AG commenced the latest 600 V TRENCHSTOP™ Performance IGBT offering the next level of competency. The state-of-the-art discrete IGBT delivers high energy efficiency and reliabeness at an aggressive price point for applications like air conditioning, solar PV inverters, drives and uninterruptible power supply (UPS). Based on Infineon’s TRENCHSTOP technology,the latest IGBT is optimized for hard switching topologies working at frequencies of up to 30 kHz. The latest TRENCHSTOP Performance IGBT series incorporates the best trade-off between conduction and switch-off energy losses with exceptional toughness. 5 µsec short circuit capacity and fantastic electromagnetic interference (EMI) behaviour. The 600 V TRENCHSTOP Performance is a great alternative to the predecessor TRENCHSTOP IGBT from Infineon as well as to contending products. In a plug-and-play replacement the new TRENCHSTOP Performance IGBT yields lessened losses of 7 percent at switching frequency of 8 kHz. A matchless 11 percent lower aggregate loss is delivered for switching frequency of 15 kHz. Making use of the same packages, redesigns for higher efficiency and competitive cost can be realized simply, fast and with less efforts. The 600 V TRENCHSTOP Performance IGBT contributes to more energy efficient power consumption, higher reliability and longer operational lifetime of the application. For end consumers this translates into a lower electricity bill, sustainability and environmental protection. Read more >>

12

Jun

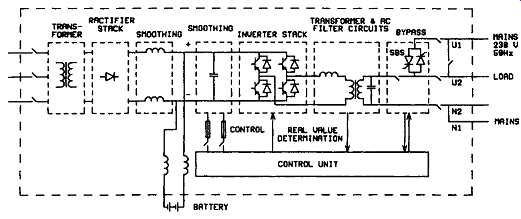

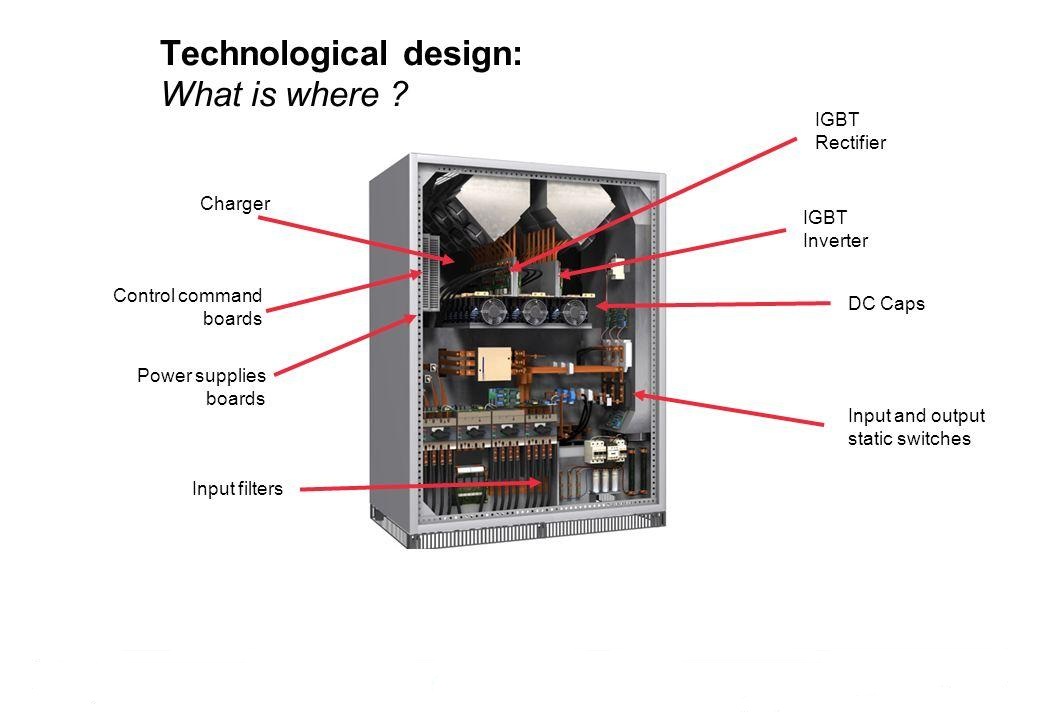

UPS (Uninterruptible Power Supply) is considered as one of the best ways to save electrical equipments from power problems. It is an electrical apparatus that provides emergency power to a load when the input power source, typically mains power fails. At home we need UPS when we use our PC. Others areas that need UPS are data centre, process backup, military operation etc. There are several varieties of UPS: online UPS, offline UPS and line interactive UPS. Online UPS is inverter supply directly to load; offline UPS is the inverter starts only when utility is not present, line interactive UPS is an offline UPS with an AVR / line conditioner. There is an inverter which converts DC current (Battery power) to AC current is called UPS inverter. IGBT rectifier technology is the latest and most effective technology in the UPS industry. It uses the high frequency to rectify the AC to DC. IGBT rectifier reduces harmonics substantially and reduces the upsize of upstream components. Hence, reduce initial cost and operation cost. Read more >>

12

Jun

El convertidor de frecuencia del sistema proporciona una solución completa para aplicaciones de media tensión

El convertidor de frecuencia del sistema proporciona una solución completa para aplicaciones de media tensión PARTE 1 La Serie MVW3000 de variadores de velocidad de WEG ha presentado nuevos aparatos con muchisimas funciones tales como: El variador de velocidad variable de media tensión MVW3000, que cuenta con una eficiencia, densidad de potencia y fiabilidad extremadamente alta, se vende como un sistema completo integrado en un armario de distribución. WEG ha presentado tambien en la serie MVW3000 de variadores de velocidad para voltajes de 2.3kV a 8kV y niveles de potencia de 28 kW a 2.400kW. Esta familia de dispositivos está construida con tecnología multinivel y puentes H en cascada (CHB). La topología multinivel se basa en la conexión en serie de tres a diez módulos de alimentación de baja tensión (690 V) con convertidores de salida IGBT en configuración de puente en H, dependiendo de la tensión de salida. Esto permite alcanzar niveles de voltaje en la gama de voltaje medio utilizando componentes de baja tensión estándar probados (diodos, IGBT y condensadores de película de plástico) de una manera rentable. Como característica especial, el MVW3000 se suministra como un sistema completo integrado en un armario de distribución, incluyendo aislador de media tensión, fusibles, transformador de alimentación multinivel y convertidor de frecuencia "El actual voltaje y rango de potencia es sólo la primera etapa en la evolución del producto. Mayores tensiones y niveles de potencia ya están disponibles bajo petición ", dijo Johannes Schwenger, jefe de sistemas de control de producto de baja tensión y media tensión de Europa en WEG. "El MVW3000 es una solución todo-en-uno de alto rendimiento que elimina la necesidad de aparatos de conmutación de media tensión adicionales. Este sistema de transmisión de velocidad variable cuenta con excelentes parámetros de entrada y salida, eficiencia energética y alta disponibilidad, junto con un fácil mantenimiento, modularidad y manejo suave del motor. Esto hace que este sistema de accionamiento de velocidad variable sea el complemento ideal para todos los motores de media tensión comercialmente disponibles y la elección perfecta para proyectos de retrofit gracias a su voltaje de salida virtualmente sinusoidal ", si deseas saber mas de estos nuevos implementos acompañanos en la parte 2 de este articulo. El sistema de accionamiento de velocidad variable MVW3000 proporciona un rendimiento de conducción extremadamente alto. El factor de potencia de red es superior a 0,95 en toda la gama de revoluciones del motor, sin ningún filtro de armónicos adicional o condensadores de compensación. La arquitectura de dispositivo integrada proporciona unas cifras de distorsión armónica de red sobresalientes para corriente y tensión (THD I / V y TDD) según IEEE 519, IEC 61800-3 y G5 / 4-1. El dispositivo cumple con los límites establecidos en estas normas, incluso en su configuración básica. El rendimiento del inversor, incluido el transformador, supera el 95 por ciento en toda la gama de velocidad del motor y es superior al 96 por ciento con niveles de carga superiores al 40 por ciento. El circuito de carga para el transformador de potencia multinivel asegura la magnetización del núcleo del transformador sin corrientes de arranque y una carga suave de los condensadores de enlace de CC para la etapa del inversor. El transformador de potencia permite la adaptación de la tensión de red a la tensión de salida del motor y la reducción de la tensión de modo común en el devanado del motor. También reduce las corrientes de modo común a través de los cojinetes del motor para maximizar la vida del rodamiento. Las interfaces entre la CPU del convertidor de frecuencia y la etapa de potencia para el control IGBT, la supervisión de la temperatura, la realimentación de la tensión y la realimentación de la corriente se implementan utilizando fibra óptica para aumentar la inmunidad al ruido y proporcionar un aislamiento efectivo entre las secciones de control y potencia. Las etapas de potencia (puentes H) están construidas con condensadores de película de plástico, fusibles semiconductores y una función de bypass automático del inversor para proporcionar una mayor disponibilidad del sistema en caso de fallo. El voltaje y la corriente de salida prácticamente sinusoidales reducen la disipación de potencia, las vibraciones y la pulsación de par en el motor. Con el fin de mejorar la fiabilidad y la disponibilidad del sistema, el MVW3000 está equipado con dispositivos de protección del motor para la protección contra sobrecarga, sobrecalentamiento y bloqueo del rotor del motor. Las temperaturas de la etapa de potencia y del transformador también se monitorean constantemente. Como sistema de empaque, el MVW3000 simplifica la instalación y puesta en marcha. Las etapas de potencia de enchufe facilitan el mantenimiento y el reemplazo rápido. Con dimensiones de 3.900 x 2.210 x 1.100 mm (An x Al x D), el sistema de accionamiento de velocidad variable también tiene una pequeña huella. Además, opcionalmente puede equiparse con todos los protocolos de comunicación industriales más habituales, incluyendo Modbus, Profibus, Devicenet y Ethernet. Read more >>

13

Jun

Modern train traction systems use high-speed switching IGBTs in main circuits. High-speed switching reduces electromagnetic noise generated by the main motor and improves the efficiency of energy conversion. For the inverter control system, vector control is employed to control the torque current component and the exciting current component separately, which are output to the induction motor. Since vector control ensures high-speed torque control, it is also applied to slip-slide control to improve adhesion force. The maintenance work for contacts and pneumatic parts can be eliminated by replacing mechanical contacts in each unit with electronic contacts and by changing the pneumatic operation system to an electromagnetic one. The numerous advantages of insulated gate bipolar transistor (IGBT) power modules and their ongoing development for higher voltage and current ratings make them interesting for traction applications. These applications imply high reliability requirements. One important requirement is the ability to withstand power cycles. Power cycles cause temperature changes which lead to a mechanical stress that can result in a failure. Lifting of bond wires is thereby the predominant failure mechanism. A fast power cycling test method activating the main failure mechanism has been developed which allows reproduction of millions of temperature changes in a short time. The applicability of fast testing is supported by a mechanical analysis. Read more >>

13

Jun

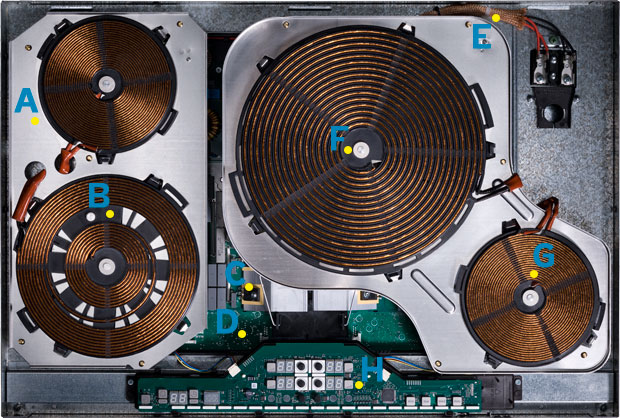

The inductive cook top creates a flat smooth surface that is easier to clean making it attractive to consumers. An induction cooker transfers electrical energy by induction from a coil of wire into any pot made of material which is electrically conductive and ferromagnetic. A coil of wire is mounted under the cooking surface and a large alternating current is passed through it to transfer power to the pot. When an electrically conductive pot is brought close to the cooking surface, the magnetic field induces an electrical current in the pot. The current flowing through the electrical resistance in the pot causes electrical power to be dissipated as heat. The heating of the pot can be used for cooking the food. Induction cook tops have become very popular displacing most resistive heated cook tops. The power circuit used to deliver power to the pot via the coil must operate at a relatively high frequency of 25-50 kHz when compared with motor drive inverters. In order to reduce the switching losses in the IGBTs, the typical circuit topology is based up on resonant converters. Soft-switching circuit operation greatly reduces power losses during the switching transient in IGBTs providing high efficiency circuit operation. Many companies have developed optimized IGBT structures for this application due to the large market size. Read more >>

14

Jun

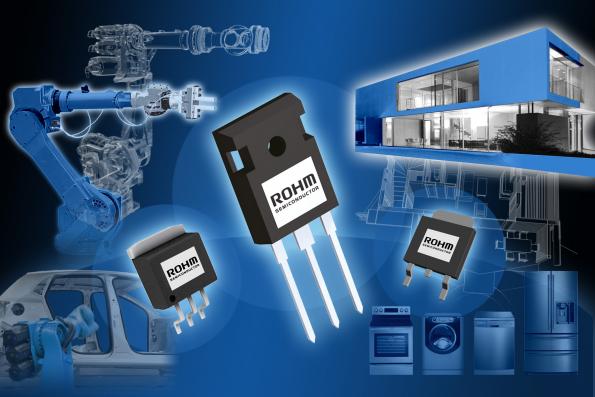

Los semiconductores de potencia, entre ellos los IGBT, están ganando aceptación debido a su implementación en muchos tipos de aplicaciones de alta tensión. Sin embargo, se espera que estos componentes alcancen una alta eficiencia y fiabilidad además de mantener unos bajos niveles de pérdidas. Al ampliar su gama existente, formada por IGBT para alta corriente e IGBT con una menor tensión de saturación y una conmutación más rápida, Rohm presenta ahora su 3ª generación de IGBT para una alta eficiencia. Los nuevos dispositivos utilizan una estructura de oblea más fina, así como tecnologías de atenuación de campo y estructura propia de puerta de zanja para obtener las prestaciones más avanzadas con el fin de cubrir la creciente necesidad de conmutación a alta frecuencia. Los nuevos IGBT de 650V de 3ª generación de Rohm, basados en una estructura avanzada de atenuación de campo, ofrecen un menor gradiente de concentración de portadores en la región de deriva que permite mejorar la distribución de los portadores. Gracias a ello es posible reducir la tensión de saturación y aumentar la velocidad de conmutación, logrando así un excelente compromiso entre la tensión de saturación y las pérdidas en el paso a corte, a diferencia de las soluciones convencionales. Read more >>

15

Jun

Los motores sin escobillas se utilizan frecuentemente en aplicaciones (H) EV. Estos motores altamente eficientes se basan en sensores de posición del rotor rápidos y precisos para conmutación, ya que estos parámetros del sensor tienen un impacto significativo en el comportamiento de arranque, la dinámica, la ondulación del par y la eficiencia. Existen diferentes principios para detectar la posición del rotor: resolución electromecánica (inductiva) y magnética. Los sistemas de sensores basados en resolver las problematicas de los transitores tienen algunas limitaciones (salida analógica, circuito complejo, altos costes del sistema, limitaciones de espacio, sensibilidad a campos perdidos y tolerancias de posicionamiento, etc.). La familia de microcontroladores AURIX de 32 bits, con su ADC delta-sigma para realizar la generación de señales portadoras y la codificación basada en software, ya ayuda a ahorrar el IC de resolución externa y, por lo tanto, el coste del sistema en un 20%. Por otro lado, los sensores de ángulo resistente a magneto (xMR) con tecnología AMR (Anisotropic-Magneto-Resistance) o GMR (Giant-Magneto-Resistance) ofrecen una precisión de alta precisión, combinada con una baja sensibilidad frente a las tolerancias de posición. Read more >>

19

Jun

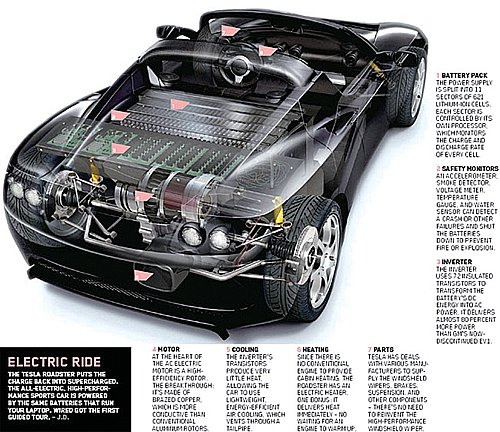

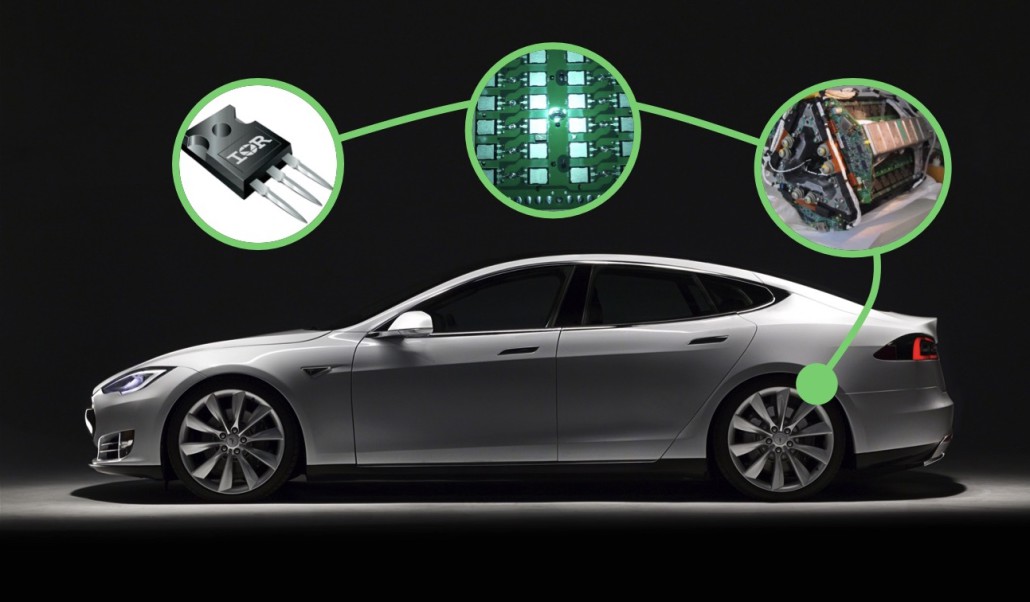

The automotive industry, largest in the world, is fast-growing and diverse, with a wide range in customer preferences for design, comfort and technology. It is well recognized that gasoline power vehicles produce significant urban pollution while consuming a dwindling fossil fuel resource. A solution to this problem is the deployment of electric and hybrid-electric vehicles. The global goals to reduce emissions and fuel consumption, with pioneering efforts in developing electric vehicles (EVs) and hybrid electric vehicles (HEVs), bring significant technology challenges. All hybrid-electric and electric cars that have been introduced into the market so far have relied up on IGBT-based motor drives. In new powertrain generations such as EVs and HEVs, IGBTs play the key role in order to drive the electric motor or store the energy. IGBTs run at very high frequencies and under high power which makes them vulnerable to thermal problems. Thermal characterization helps to optimize the IGBTs layout, structure and mounting to optimize its performance. After all we can say, the availableness of IGBTs has been diametrical to the advancement of the hybrid vehicles and to the expansion of the charging substructure for the electric vehicles. IGBTs will carry on playing a significant part in the availableness of expense reducing technology for the whole hybrid and electric vehicle business. Read more >>

20

Jun

El fabricante líder mundial en tecnología de motores y de accionamientos, presenta la nueva serie de variadores de velocidad MVW3000 con tensión nominal desde 2,3kV a 8kV y potencia nominal de 280 kW a 2.400 kW. Esta familia de dispositivos incorpora tecnología multinivel y puentes H en cascada (CHB). La topología multinivel está basada en la conexión en serie de tres a diez módulos de potencia IGBT de baja tensión (690V), dependiendo de la tensión de salida. De este modo, se pueden alcanzar niveles de tensión en el rango de media tensión utilizando, de manera rentable, componentes de baja tensión estándares probados (diodos, IGBTs y condensadores de película de plástico). Como característica especial, el MVW3000 se suministra como un sistema completo integrado en un armario de distribución, incluyendo interruptor de desconexión de media tensión, fusibles, transformador de alimentación multinivel y módulo de velocidad variable. “El actual rango de tensión y potencia es solamente la primera etapa en la evolución del producto. Hay tensiones y potencias más elevadas disponibles si se solicitan,” comenta Johannes Schwenger, Jefe de Producto para Sistemas de Accionamiento de Baja y Media Tensión en Europa para WEG., y añade: “El MVW3000 es una solución integral de alto rendimiento que no necesita ninguna aparamenta de media tensión adicional. Este sistema de accionamiento de velocidad variable se distingue por sus extraordinarios parámetros de entrada y salida y sus excelentes niveles de eficiencia energética y disponibilidad, además de un fácil mantenimiento y un tamaño compacto pero eficiente que les permite ser usados en muchos campos. Read more >>

20

Jun

The best way to protect electronic equipments from power problems is using UPS. UPS units have different sizes, from little desktop system that shields an individual PC to massive UPS that can supply power to a whole building. Nearly every organization has a power safeguard necessity, ranging from companies with computer UPS provides power to your equipment in the case of an entire power collapse, giving you opportunity to save data and close files. At a more commencing level, the UPS conditions and filters networks to hospitals, airports, oil rigs and anywhere where uninterrupted power is must. Today maximum industries are using UPSs to save their core business against mains failures, mains supply fluctuations, power surges, and other troubles in the electrical supply. The option of picking a Rotary or Static UPS for industrial applications has become contentious and the myths require rectification. Over recent years, Static UPSs have captured a large share of the UPS market when compared to the Rotary type, although Rotary UPSs still sustain popularity in industrial environments where ratings are in excess of 800kVA. The drawback is however, that Rotary technology is usually 30% more costly than the substitute Static offerings. Now-a-days, Static UPSs are a major rival for industrial installations, and the conveniences and benefits they offer, have seen consultants considering their design criteria from Rotary to Static technology. Outward appearances and inverters of Static UPS have changed amazingly in modern years with thyristor technology being replaced with IGBT technology. This recent technology has assisted notably to enhance the potency and managing of non-linear loads (computers and SMP type loads) with excessively low voltage distortion. With thyristor technology, peaks of the voltage wave form were frequently flattened, whereas this does not happen with the more recent IGBT technology. A moreover advantage of IGBT is that it minimizes the size of the inverter stacks and makes allowance for repairs to be done more effortlessly. And, owing to digitally controlled UPS design and growth in the IT arena, it is now very simple to monitor UPSs remotely from a different site or even from another country. Read more >>

21

Jun

Un aumento excesivo o inesperado de la temperatura interna puede conducir a la evaporación del agua ya la pérdida de refrigerantes en los sistemas críticos de enfriamiento de la turbina, y eventualmente puede causar que la electrónica de la turbina se sobrecaliente. Esto es una preocupación particular en las máquinas con un sistema de refrigeración de lazo abierto y puede ocurrir incluso con el uso de refrigerantes de alta calidad. Un sistema de bucle abierto permite que el agua se evapore gradualmente desde el refrigerante de agua-glicol en el circuito de transistor bipolar de puerta aislada (IGBT), particularmente durante el tiempo cálido. (Los IGBT son un componente electrónico utilizado típicamente en turbinas debido a sus capacidades de conmutación rápidas y eficientes.) Un problema puede ocurrir cuando la evaporación del agua disminuye el nivel del refrigerante y eleva la concentración de la mezcla. Si el sistema se deja sin control y no se mantiene, el desequilibrio de mezcla resultante inhibe las propiedades de enfriamiento del fluido. Esto potencialmente compromete el IGBT. Huelga decir que una pérdida de componentes IGBT debido al sobrecalentamiento puede resultar en costosas pérdidas de hardware y un tiempo de inactividad significativo de la turbina. Para evitar esto, los operadores de viento han "vendado" el problema con una cadencia regular de monitoreo de refrigerante, reposición de agua y reequilibrio de la mezcla de fluido refrigerante. Este enfoque puede funcionar cuando se respeta diligentemente, pero es un costoso plan de mantenimiento. Requiere tomar la turbina y el transformador fuera de línea, lo que también significa tiempo de inactividad de la turbina y pérdida de ingresos para el parque eólico. Read more >>

21

Jun

The IGBT has a major impact on the transportation sector in all over the world. It enabled the introduction of cost effective and reliable electronic ignitions systems that have improved gasoline fuel efficiency by at least 10 percent. They have also been critical elements in the improvement of mass transit systems and the deployment of electric and hybrid electric vehicles. Modern mass transit systems rely up on electric trains where the propulsion is derived from supplying AC power to motors. High speed rail, such as the European TGV and the Japanese Shinkansen bullet trains allows travel by large numbers of people while avoiding fossil fuel consumption experienced with gasoline powered automobiles and aircraft. Until the 1990s, the silicon GTO was the only available power semiconductor switching device with the power handling capability suitable for this application. In the 1990s, the ratings of IGBTs had sufficiently advanced, to exceed one Mega-Watt allowing penetration of the IGBT into this traction market. The availability of the IGBT allowed significant improvements in the motor drive technology due to elimination of snubber circuits and an increase in the operating frequency of the inverter circuit used to deliver power to the motors. Mass transit systems within cities must rely upon a busses, trams, and underground trains. Many cities have been replacing gasoline powered busses with electric busses and trams to reduce urban pollution. All of these below requirements were met by using the IGBT-based motor drive in control system for the electric transit bus: (a) wide range of speed including high operating speed; (b) large startup torque for good acceleration; (c) high efficiency; and (d) regenerative braking to increase utilization of batteries. In Europe and Japan, electric tram transit systems have been modernized by using IGBT-based motor drives. According to AEG-Westinghouse Transport Systeme, Germany, the low floor concept is becoming a standard customer prerequisite. This has been enabled by today’s IGBT modules. Read more >>

21

Jun

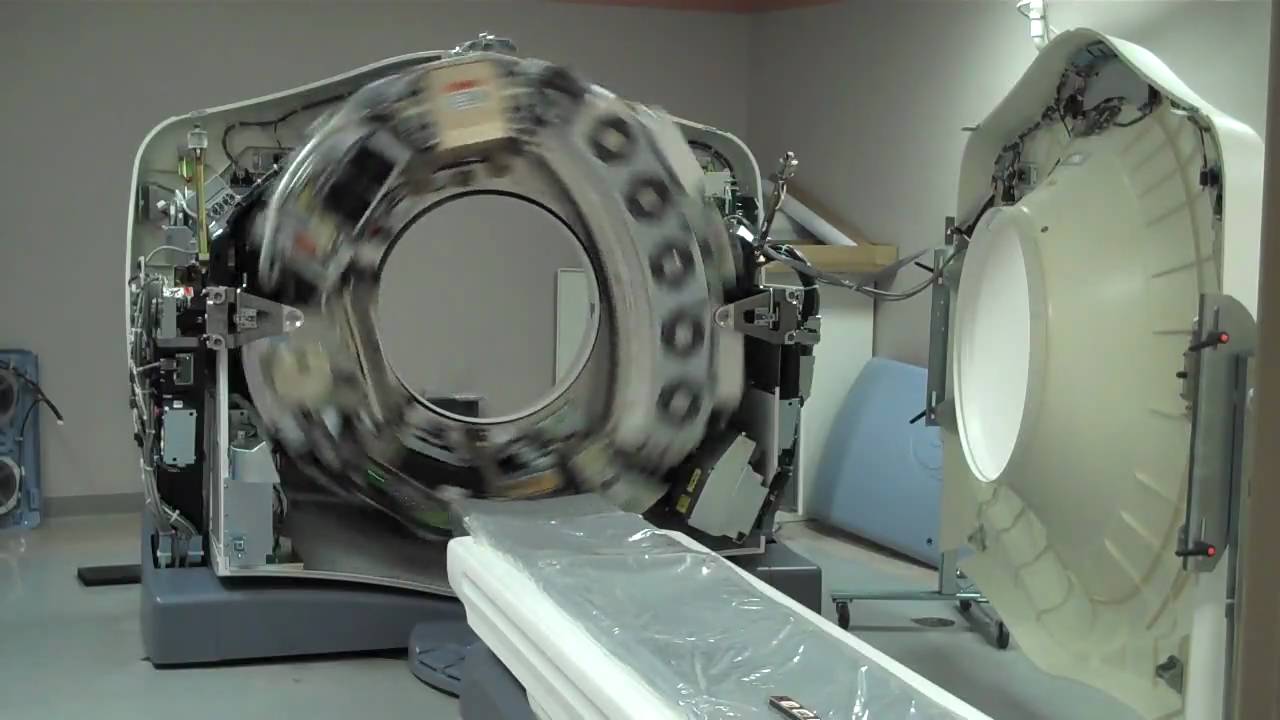

State-of-the-art medical diagnostic equipment has transformed the quality of care for our society. Non-invasive imaging of the interior of the body enables the surgeon to perform operations while minimizing damage to adjacent tissue and organs. The IGBT has been used since the early deployment of CT scanners for the control of the gantry on which the patient is reclining as described below. It is also used in the power supply for X-ray and Ultrasound machines. In addition, hundreds of thousands of lives are being saved due to the availability of portable defibrillators which require IGBTs for delivering the controlled shock to the patient of cardiac arrest as discussed below. Computed tomography (CT) generates a three dimensional image of a patient using a large series of two dimensional images taken around a single axis of rotation. The image is generated by viewing the patient using x-ray imaging from numerous angles. A single plane of a patient is scanned from various angles in order to provide a cross-sectional image of the internal structure of that plane. A three-dimensional view can then be created by mathematical analysis that combines the images. The gantry on which the patient is reclining is positioned using closed loop feedback control of motors in order to accurately move and position the patient. An IGBT-based motor drive is employed by all manufacturers, such as GE, Philips, and Siemens, for precise and controlled movement of the gantry. The CT scanner contains an X-ray tube with detectors located diametrically opposite the X-ray source which are rotated around the patient to generate a section image. CT scanners can provide detailed cross-sectional images of nearly every part of the human body including the brain, neck, shoulders, cervical spine, heart, lungs, abdomen, liver, kidney, pelvis, etc. Read more >>

27

Jun

KV-CEI aísla sistemas electrónicos de contaminantes aéreos, polvo, químicos y evaporación de vapor de agua. Es un recinto que funciona cerrando el sistema de circuito de refrigeración de la atmósfera exterior (donde escapa la evaporación) con una cámara de respiración. El aire exterior infla y desinfla la vejiga cuando los niveles de fluido dentro del tanque de aislamiento se expanden y se contraen de los cambios de temperatura del líquido del sistema. Una válvula de alivio de baja presión ayuda a prevenir la sobre-presurización del sistema en caso de que el aire imprevisto quede atrapado dentro de las líneas de fluido. Una válvula de cierre abierto que extrae aire permite que el sistema drene y rellene con los niveles de fluido adecuados durante un ciclo de mantenimiento preventivo normal. Al aislar el volumen interno del depósito de la atmósfera exterior existente, el sistema impide la evaporación del agua y la entrada de contaminantes en el aire en la solución de agua-glicol. Una válvula de retención proporciona protección contra sobrepresión y un indicador de nivel visual permite la confirmación local del nivel de refrigerante. Además, un puerto permite añadir un interruptor flotante opcional de nivel de líquido estándar para la indicación remota de refrigerante de bajo nivel. "El diseño de KV-CEI es lo suficientemente versátil como para permitir la adición de sensores de bajo nivel de líquido cuando sea necesario en una turbina". Mosher dice que los diseños personalizados también son posibles. "También podemos diseñar muchas opciones de montaje para adaptarse a un patrón de montaje particular". El objetivo es mantener las turbinas eólicas generando energía incluso en temperaturas extremas, sin añadir más visitas de mantenimiento a un sitio. "El retorno de la inversión para la solución KV-CEI se puede medir en tan sólo unas pocas semanas en climas más cálidos ya temperaturas de operación elevadas", dice Mosher. Read more >>

27

Jun

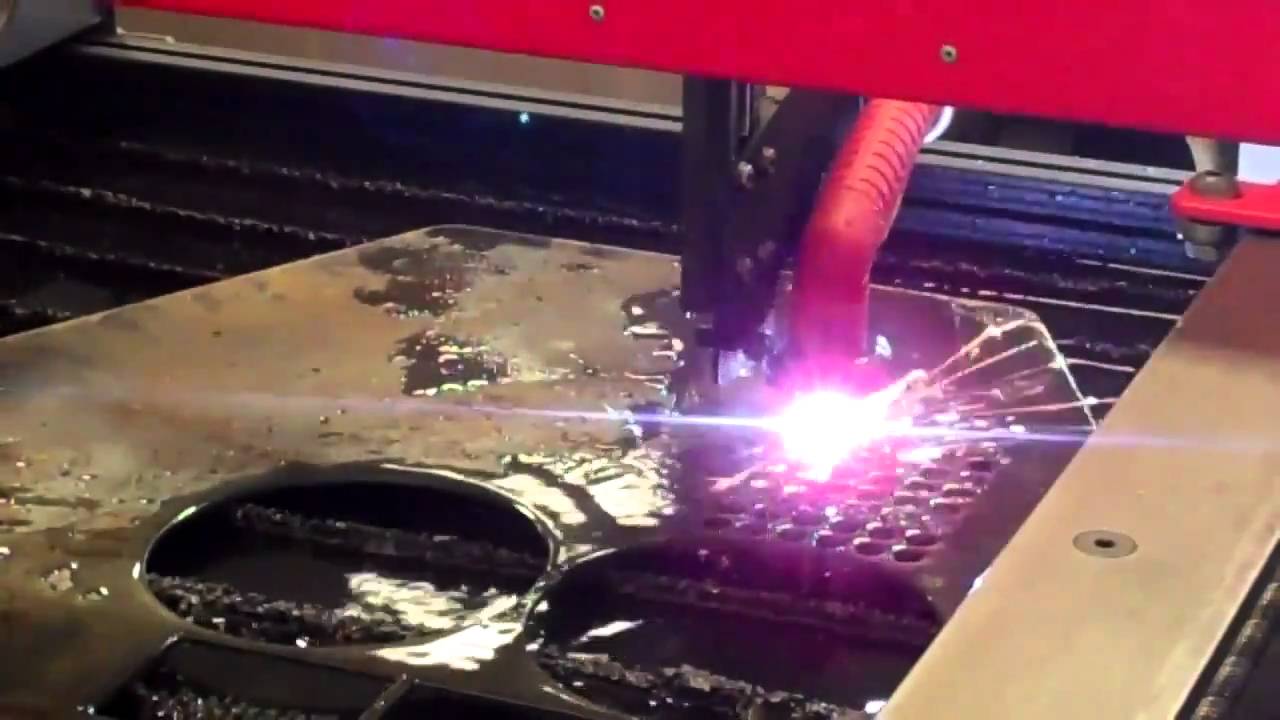

Plasma cutting involves cutting a material using a plasma torch. It is commonly used to cut steel and other metals, but can be used on a variety of materials. In this process, gas (such as compressed air) is blown at high speed out of a nozzle; at the same time an electrical arc is formed through that gas from the nozzle to the surface being cut, turning some of that gas to plasma. The plasma is sufficiently hot to melt the material being cut and moves sufficiently fast to blow molten metal away from the cut. The transistors used in plasma cutting were initially MOSFETs, but are now increasingly using IGBTs. With paralleled MOSFETs, if one of the transistors activates prematurely it can lead to a cascading failure of one quarter of the inverter. A later invention, IGBTs, is not as subject to this failure mode. IGBTs can be generally found in high current machines where it is not possible to parallel sufficient MOSFET transistors. Read more >>

30

Jun

The most effective way to save electronic equipments from power problems is using UPS. UPS units have different sizes, from little desktop system that shields an individual PC to massive UPS that can supply power to a whole building. Nearly every organization has a power safeguard necessity, ranging from companies with computer UPS provides power to your equipment in the case of a entire power collapse, giving you opportunity to save data and close files. At a more commencing level, the UPS conditions and filters networks to hospitals, airports, oil rigs and anywhere where uninterrupted power is must. Today maximum industries are using UPSs to save their core business against mains failures, mains supply fluctuations, power surges, and other troubles in the electrical supply. Spontaneous control, outstanding switching features and excellent reliability make IGBTs the perfect option today for medium and high-power UPS. These modules greatly enhance UPS performance, specifically in terms of proficiency, acoustic noise, shaped and weight. In high capacity UPS where the inverter functions between 2 and 4 kHz, the prime benefit of the IGBT is simplification of transistor control (better reliableness). IGBT is comparable to the bipolar transistors in terms of efficiency. Read more >>

28

Jul

The fixing system for the toner in copy machines, laser printers, facsimile machines, data recorders, and scanners needs transfer of toner from the rolling drum to the printing paper with heat and pressure. Radiant heating with halogen lamps was used for this process in the past. However, nearly 90 percent of the printing energy is consumed by this operation. The efficiency can be improved by using the induction heating approach leading to reduction of the size of the printing devices. The induction heating coil is installed concentrically inside the fixing roller. The high frequency inverter required to feed the inductive energy into the heating coil is built using IGBTs. The actual high efficiency of more than 94 percent of the series resonant ZCS-PDM high frequency inverter for IH roller in copy and printing machines has been observed for all the output AC power regulation ranges from 50 to 1200 W. Read more >>

28

Jul

PWM VFD operations need great switching speed which can be attained by using IGBTs (insulated gate bipolar transistor). Switching on and off several thousand times a second is one of the main attributes of IGBTs. A VFD IGBT can turn on in less than 400 nanoseconds and off in about 500 nanoseconds. It is composed of a gate, collector and an emitter. When a positive voltage (typically +15 VDC) is applied to the gate the IGBT will turn on. This is same to closing a switch. Current will flow between the collector and emitter. A VFD IGBT is turned off by removing the positive voltage from the gate. During the off state the IGBT gate voltage is generally held at a small negative voltage (-15 VDC) to restrain the device from turning on. IGBTs are used as power devices by all recent VFDs. These devices make it possible to reduce annoying audible noise by using switching frequencies beyond the audible range. Unfortunately, VFDs using IGBTs, present a high potential for generating RFI - Radio Frequency Interference. Fast switching in these devices generates sharp-edged waveforms with high frequency components that generate more RFI. The most probable complaint is interference with AM band radios 500-1600 kHz. However, sensitive computers, medical equipment and other interference-sensitive devices sharing the same power buss could experience significant interference. In extreme conditions, the VFD itself can experience electrical noise interference. If elevator machine room equipment is not properly laid out and correctly wired, the electrical noise propagated by the elevator VFD system can intervene with the elevator controller. The switching speed, simple control and overload withstand of the IGBT currently make it a component of considerable interest. Read more >>

28

Jul

Heart specialists, neonatologists, obstetricians, urologists, gastroenterologists use ultrasound based imaging extensively for diagnosis and treatment of patients. Sound waves above the audible range of humans are called ultrasound. The choice of the ultrasound frequency for diagnostic purposes is a trade-off between image resolution and special depth. Due to the longer wavelength of the sound wave, lower ultrasound frequencies produce images with less resolution, although these penetrate deeper into the body. Normal ultrasound frequencies range from 2 to 18 MHz. A hand-held probe is used to perform Sonography that is placed and moved over the patient while viewing the image in real time. A piezoelectric transducer with a phased array is contained in the probe, which allows altering the direction and depth of the sound wave. The sound wave is reverberated from the organs inside the body at different intensities depending upon their composition and the time taken for the echo to return to the transducer specifies the distance travelled by the wave. For diagnostic purposes, this information is converted to an image. The application of a high voltage pulse to the piezoelectric medium produces the sound wave from the ultrasound transducer. The pulse must have amplitude of over 1000 volts with a current of 20-50 amperes. Because of the short duration of the pulse, generally 0.5 microseconds, with a less operating frequency of 200-Hz, the best approach is to slowly charge a capacitor through a diode when the IGBT is off and then turn-on the IGBT for the short pulse duration to discharge the capacitor through the transducer. Read more >>

04

Aug

Rice is the first & foremost food for billions of people around the world, especially in Asian countries such as China, India, and Japan, with mass populations. According to Asian Rice Foundation, “Rice is arguably the world’s most important food. It is the second most widely cultivated cereal in the world, after wheat, and is a staple food of over half the world’s population. Rice can be cooked in a variety of ways, including boiling, baking, roasting, frying, and pressure-cooking. Cooking rice in an automatic rice cooker is becoming very popular, as it ensures consistent results and cooking instruction is much simpler to follow”. Many Asian companies have developed rice cookers based up on the induction heating principle. The induction heating can be accomplished by using an induction cooking plate or preferably by using an induction rice cooker. Two types of circuit topologies have been explored for the induction rice cooker. First one is the half-bridge series resonant converter and another is the quasi-resonant converter. The series resonant converter has the advantages of stable switching, low cost, and streamline design. The quasi-resonant converter has the advantage of a smaller design with reduced heat sink. The quasi-resonant converter is more widely used. Due to the large market for these appliances, some semiconductor companies have developed IGBT products optimized for this market for the quasi-resonant converter topology. IGBTs feature a robust and cost effective Field Stop (FS) trench construction, and provide superior performance in demanding switching applications, offering both low on-state voltage and minimal switching loss. IGBTs are well suited for this type of resonant or soft switching applications. Read more >>

04

Aug

In the highly emulative UPS market, every renowned UPS manufacturer is trying to ameliorate their UPS performance and reliability steadily. This increasing demand will only be satisfied if the components used can keep pace. IGBTs are considered as one of the best choices for medium and high-power UPS because of their simple control, great switching characteristics and excellent reliability. Especially in terms of efficiency, acoustic noise, size and weight, they remarkably uplift UPS performance. In high power UPS where the inverter operates between 2 and 4 kHz, the main benefit of the IGBT is simplification of transistor control (increased reliability). Its efficiency is equal to that of bipolar transistors. In medium power UPS often installed in computer rooms, the acoustic noise criterion makes it necessary to remove the 50 or 60 Hz transformer and to add an inverter operating at a frequency of 16 kHz, thus making the IGBT absolutely indispensable both due to the lessening in number of components required to control it and due to the gain in weight and in total dimensions. Production of new products calls for a prudent, meticulous choice of new components. We are frequently informed about the announcements of new elements as the IGBT is still in the growth stage. Present studies should not be questioned as authorized approval of a power semiconductor is long and expensive. Read more >>

15

Aug

Infineon amplió la cartera de productos de los módulos IGBT de EconoPIM 3 pulgadas. La corriente nominal del módulo se incrementa con ello de 100A a 150A. Las aplicaciones típicas para los módulos de potencia para las unidades de control de motor en ascensores, escaleras mecánicas, ventiladores o bombas. Los módulos incluyen un rectificador trifásico, un chopper de frenado, un inversor trifásico y un termistor (NTC) para la medición de temperatura. A una tensión de bloqueo de 1200V, el nuevo EconoPIM 3 alcanza una corriente máxima nominal de 150A. La carcasa está equipada con una placa de base y corresponde en dimensión a la norma de la industria. Puede ser incorporado en los diseños existentes. Cuando se utiliza en las unidades EconoPIM 3 permite de acuerdo con el proveedor en el mismo tamaño de hasta 30 por ciento más de potencia de salida. Los módulos de usar el chip IGBT4 con la tecnología TrenchStop, robustez y fiabilidad. Disponibilidad: El módulo EconoPIM con 1200V / 150A está disponible con pines de soldadura o pernos press-fit. Esto se aplica a todas las variantes con el chip IGBT4 en la tecnología TrenchStop. Además, los módulos opcionales con material de interfaz térmica (TIM) están disponibles. Los módulos de potencia están disponibles en la producción de volumen, las muestras están disponibles. Read more >>

15

Aug

In a typical HVDC power transmission system, the power is transmitted at very high voltages (above 100-kV) in order to reduce the current on the cables. Large currents in cables require more copper which adds to the cost and weight. Since power semiconductor devices are unable to withstand such high voltages, it is necessary to connect many devices in series to satisfy the system requirements. In addition, for higher power levels, many devices may have to be connected in parallel as well. The series and parallel combination of power devices comprises an HVDC valve. The most common configuration for modern overhead HVDC transmission lines is bipolar because it provides two independent DC circuits each capable of operating at half capacity. Two basic converters topologies are used in modern HVDC transmission systems: conventional line-commutated, current-source converters (CSC) based up on thyristor-valves and self-commutated, voltage-sourced converters (VSC) based up on IGBT-valves. Each valve consists of a large number of series connected thyristors or IGBTs to sustain the desired DC voltage rating. In the case of current source converters with thyristor valves, a Graetz bridge configuration is used allowing six commutations or switching operations per period. Self-commutated, voltage-source converters using IGBTs are preferred because they allow independent rapid control of both active and reactive power. Reactive power can also be controlled at each end of the transmission line providing total flexibility in network design. The self-commutated, voltage source converters can be constructed using IGBTs without the snubbers required for GTOs. The rate of rise of the current in the IGBT can be controlled by tailoring the gate drive voltage waveform without any ancillary components. This allows controlling the reverse recovery of the anti-parallel rectifiers without the snubbers. The reduced passive components in the IGBT-based VSC inverters reduce system cost. Read more >>

17

Aug

Refrigerators have become essential appliances in society for the preservation of food and beverages. The quality of life for people has been greatly enhanced with the availability of affordable refrigerators for homes. Most household refrigerators utilize the vapor compression cycle with a circulating refrigerant used to cool the refrigerator compartment. Household refrigerators originally used an on/off controlled, constant-speed, single-phase induction motor to drive the compressor. The poor efficiency of this approach made the refrigerator one of the highest power consumption appliances in the home. In order to improve the efficiency, modern refrigerators with the Energy star rating utilize variable-speed, three-phase induction motor drives. Current models that are Energy Star qualified use 50 percent less energy than the average models made in 1974. The variable speed drive to the induction motor is provided using the six IGBTs in the inverter stage. The author’s state: “The total energy savings was about 40%. The system is very quiet and maintains a constant temperature within 0.1 degree Celsius which improves the quality and shelf life of food stored in the refrigerator.” Many companies have optimized IGBTs for use in refrigerator compressor drives due to the large market opportunity. Some companies have developed intelligent power modules, which combine the IGBTs, fly-back rectifiers, and the drive circuits into a single module. This provides a very compact and low cost motor drive option that can be easily adopted for the manufacturing of refrigerators. Read more >>

17

Aug

A vacuum cleaner is an appliance that uses an air pump to create a partial vacuum to suck up dust and dirt from floors, and other surfaces. The dirt is collected by a dust-bag for future disposal. Hubert Cecil Booth invented the motorized vacuum cleaner in 1901. Since then, their use has proliferated and vacuum cleaners are now very commonly used in homes on a regular basis to maintain a healthy living environment. Manufacturers of vacuum cleaners include Eureca, Hoover, Bissell, and Dyson. In the past, universal motors were mostly used for vacuum cleaners due to high operating speed with low cost. However, these motors use a mechanical brush which wears out at high speeds limiting the performance. Modern vacuum cleaners with higher output power (suction) are designed using switched reluctance motors. The power circuits used for operation of the switched reluctance motor in vacuum cleaners. These circuits utilize IGBTs to overcome the difficult start-up problem for switched reluctance motors and for maintaining a high operating speed. The author’s state: “Its lifetime is extended 4 times than that of conventional motor and its suction power is increased 20% at the same volume of conventional universal motor”. Read more >>

07

Sep

Microwave ovens are used to heat foods quickly and conveniently and it has become an inseparable part of our kitchens and offices now-a-days. It is also used for used for stewing, frying, baking, steaming, and fermenting foods. Microwave ovens are designed for tabletop use or for mounting above the range. Microwave ovens heat food by following the principle of dielectric heating using microwave radiation, usually at a frequency of 2.45 GHz, through the food. Water, fat, and other substances in the food, absorb energy from the microwaves resulting in heating. The microwaves interact with the food in a uniform fashion leading to food being more evenly heated throughout. Prior the availableness of the IGBT, the traditional power supply for the magnetron was a ferro-resonant circuit. Although simple in construction, this power supply was heavy and bulky because of the large size and weight of the low-frequency (50-60 Hz) step-up transformer. After the availability of the IGBT, a magnetron power supply based up on using a high frequency inverter was developed. In this new power supply the anode voltage of the Magnetron rises above 3500 volts when the IGBT is turned on allowing it to generate microwave energy. The power delivered by the magnetron can therefore be precisely controlled using the on-time for the IGBT. Using the IGBT-based inverter circuit, the weight of the transformer could be lessened by more than 10-times. Read more >>

07

Sep

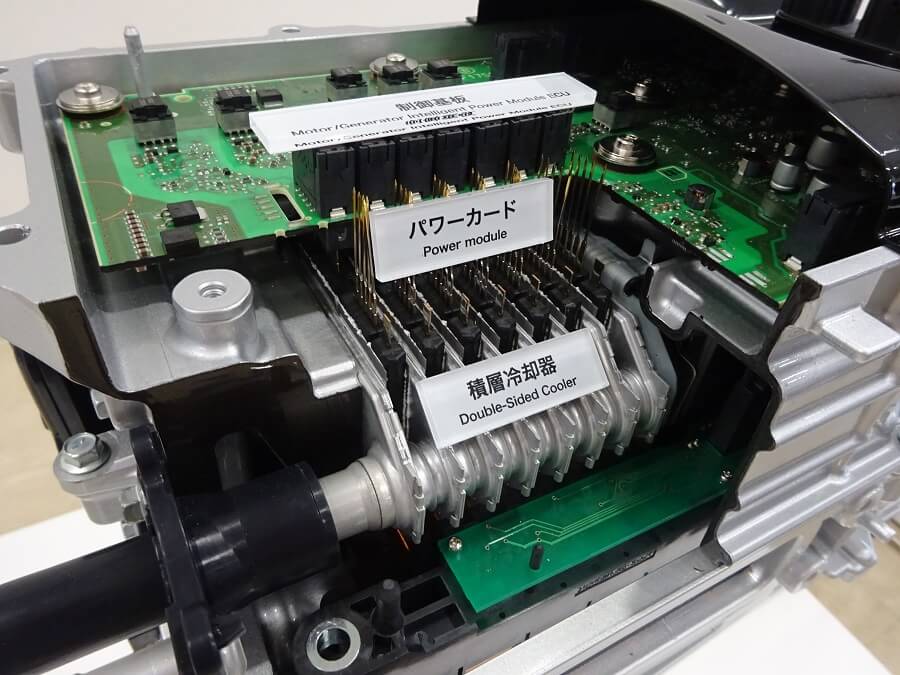

Nearly 20 years ago, IGBT modules were first commenced to be used mainly in industrial equipments, and are now being utilized in electric power conversion systems for controlling motors in a wide range of fields, ranging from household appliances such as air conditioners to applications in the railroad industry. In recent years, the extent of automotive applications has been expanded and improvement is aiming to realize IGBT modules having even higher levels of performance. A hybrid vehicle system consists of an electric motor, a battery and an inverter. An electric power conversion system is needed to supply electrical energy from the battery to the motor, and to store energy generated by the motor in the battery. The inverter is used as that power conversion system. IGBTs (insulated gate bipolar transistor) are one of the most common modules to use as the main switching device in this electric power conversion system. Hybrid systems can be broadly categorized as either a dual-motor system (traction motor and generation motor) focused on travel performance or a single motor system that combines traction and generation functions and that is focused on miniaturization. The single-motor hybrid system, known as a parallel hybrid system (hereafter referred to as a parallel hybrid), is expected to increase in popularity with application to small vehicles where the parallel hybrid advantages of small size and light weight can be fully appreciated. Read more >>

11

Sep

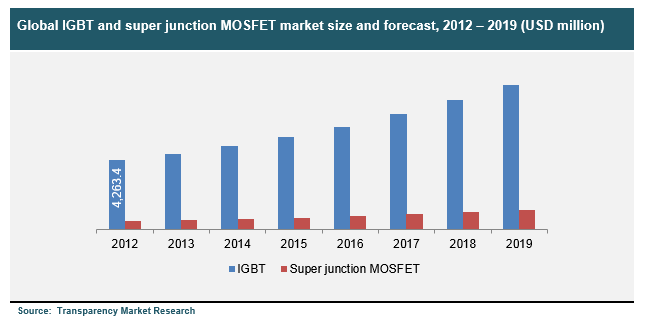

El informe de investigación MOSFET de IGBT y Super Junction se centra en los principales líderes empresariales mundiales que presentan información como perfiles de empresa, imagen del producto y especificaciones, volumen, producción, precio, costo, ingresos e información de contacto. También se dan a conocer las materias primas de las aguas arriba, además de los equipos y el análisis de la demanda aguas abajo. Se examinan las tendencias en desarrollo de la industria del MOSFET de IGBT y de Super Junction. En última instancia, la probabilidad de nuevos proyectos de financiación se evalúan y en general IGBT y Super Junction MOSFET investigación conclusiones ofrecidas. Con 150 tablas y cifras, el IGBT y Super Junction MOSFET mercado informe contribuye a las estadísticas clave sobre el medio ambiente de la industria y es una importante fuente de liderazgo y administración para las empresas e individuos que participan en el IGBT y Super Junction MOSFET mercado. Preguntas clave respondidas en este IGBT y Super Junction MOSFET informe de investigación de mercado 2017-2022: ¿Cuál será el tamaño del mercado MOSFET IGBT y Super Junction en 2020 y cuál será la tasa de crecimiento? ¿Cuáles son las principales tendencias del mercado de MOSFET IGBT y Super Junction? ¿Qué está haciendo el mercado de MOSFET de IGBT y Super Junction? ¿Cuáles son las provocaciones al crecimiento del mercado MOSFET de IGBT y Super Junction? ¿Quiénes son los hombres de negocios clave en el espacio IGBT y Super Junction MOSFET? ¿Cuáles son las posibilidades del mercado de MOSFET de IGBT y Super Junction y las intimidaciones a las que se enfrentan los principales proveedores? ¿Cuáles son los poderes y las tendencias de los vendedores IGBT y Super Junction MOSFET mercado clave? Read more >>

13

Sep

Aunque el segmento de potencia discreta y módulo es un mercado maduro, es dominado hoy por Infineon, que tiene dos veces los ingresos del segundo fabricante de estos productos, dijo el Dr. Pierric Gueguen, gerente de unidad de negocios, Yole Développement. "En este mercado, esta posición no es adecuada a largo plazo. Esperamos que el mercado continúe consolidándose para obtener más activos para competir con el líder del mercado. La adquisición de IXYS es un ejemplo, así como la adquisición de Fairchild por ON Semiconductor el año pasado ". "Con la adquisición de IXYS, Littelfuse confirma su presencia y posición como proveedor de IGBT", agregó Gueguen. "Littelfuse se beneficiará de los diseños de dispositivos IXYS y conocimientos de empaquetado de módulos, así como una sólida cartera de patentes para acelerar su desarrollo tecnológico y sus ingresos". Antes de la adquisición de IXYS, Littelfuse adquirió la línea de productos IGBT de ON Semiconductor en septiembre de 2016. El negocio generó menos de $ 25 millones en ingresos en el año fiscal de 2015. La mayoría de los jugadores de IGBT ofrecen soluciones discretas y de módulos en el rango de voltaje medio de 600V a 1300V, que representa más del 60 por ciento del mercado mundial de IGBT, dijo Yole. Read more >>

13

Sep

Alfa y Omega Semiconductor Limited (AOS), diseñador, desarrollador y proveedor global de una amplia gama de semiconductores de potencia y circuitos integrados de potencia, está ampliando su familia de conmutadores de conmutación rápida 650V H-series IGBT 1200V clasificación. El nuevo AOK40B120H1 ha sido desarrollado para satisfacer las necesidades de soldadura industrial y convertidores de alta frecuencia con entrada trifásica de corriente alterna o alta tensión. El dispositivo ofrece un excelente rendimiento en aplicaciones de alta frecuencia de conmutación, que puede ser un ajuste perfecto para máquinas de soldadura industriales de alto voltaje. El AOK40B120H1 ha sido diseñado con la plataforma tecnológica AlphaIGBT ™ de patente pendiente de AOS y cuenta con un sistema de encendido rápido y un VCE (SAT) de 1,8 V, lo que reduce las pérdidas de potencia durante la conducción y la conmutación. Además, la clasificación mínima de BVCES de 1200V y la alta robustez de enganche permiten un diseño de aplicación de seguridad más grande. "El AOK40B120H1 aborda exhaustivamente las necesidades de los diseñadores de sistemas de soldadura discretos basados en IGBT de 1200V. El alto rendimiento, como la baja VCE (SAT) y la baja pérdida de los comportamientos de conmutación de apagado garantizan una operación confiable y altamente eficiente, permitiendo a los diseñadores aprovechar la rentabilidad ", dijo el Dr. Brian Suh, vicepresidente de la línea de productos IGBT de AOS. "Los IGBT de AOS están en una posición única para abordar los puntos de dolor de los clientes con tecnología y soluciones innovadoras". Read more >>

20

Sep

For locomotives, which are driven by diesel or electricity, EMU and DEMU vehicles with AC Traction Motors, new microprocessor based AC-AC Traction System (MAS) offers the latest in technology combining IGBT based Traction Converter with DSP and microprocessor based embedded controls. Microprocessor based Locomotive Control system is used in conjunction with IGBT based traction converter to implement this solution. Every traction converter can be configured to have single or multiple inverters. Each Inverter can be further configured to drive single traction motor (independent axle control) or multiple traction motors (bogie control). Existing product offering ranges from 650kW per Inverter for bogie control to 550kW per Inverter for independent axle control. Anywhere between 2 to 6 such inverters are packaged into one traction converter depending on application with total power rating in the range of 1.3MW to 3MW. Last solution can be scaled or optimized for specific application requirement. Typically heat pipe depended heat sinks are used with forced air cooling to cool down the IGBT switching devices. Both on-board as well as under frame options are available depending on space, weight constraints and cooling air availability. The blowers for cooling air are controllable at different speeds or can be turned off depending on heat sink temperatures, so as to enhance the blower life. Read more >>

22

Sep

El gigante nipon Mitsubishi is mundialmente conocido por su calidad superior en cuanto a sus modulos IGBT, hoy discutiremos acerca del CM150DY-12NF que es un modulo IGBT dual e mitsubishi CM150DY-12NF tiene una serie de ventajas sobre el MOSFET y el BJT, estas son sus ventajas: 1.Tiene una caida de voltaje muy baja debido a la modulación de su conductividad y tiene una densidad de corriente estatica tan pequeña que inclusive el tamaño del chip podria ser reducido 2. Bajo poder de conducción y conectividad , debido a la estructura del input MOS y su puente, puede ser facilmente controlado a comparación (transitores y BJT) en alto voltaje y alta corriente 3.Amplio SOA, tiene una capacidad de conducción muy superior comparada con los transistores bipolares y una excelente capacidad de bloqueo de reversa. Descripción del producto Serie de modulos duales IGBTMOD-NF, 150 amperes/ 600 voltios, cada modulo consiste de dos transistores IGBT en una configuración de medio puente, acda transistor posee una conectividad reversa de rapida recuperacion y un diodo de rueda suelta Read more >>

25

Sep

Repletion and dependability of the forklift are very important for your activities and your lifts are only as powerful as your charged batteries allow them to be. If your facility uses Ferro resonant or SCR battery chargers, you may want to consider the benefits of the high frequency opportunity chargers. You will no longer be suffered from the equipment downtime if you utilize opportunity charging. You’ll be able to utilize idle periods to charge batteries by its charging profile. Not only you will maximize the use of the truck idle time, you may eliminate the need to change batteries, reduce accidents changing batteries, eliminate the need for required battery-changing equipment and battery storage space, and reduce the number of batteries you’ll need to buy. Opportunity charging with high-frequency opportunity chargers also increases productivity by eliminating the need for an operator to leave the work area, travel to the battery room to change batteries, and then travel back to the work area. You will be able to eliminate your battery change room/area, as well as all its hotspots: charging and changing equipment and associated maintenance; a power-hungry ventilation system and its required service calls; and any upgrades to maintain OSHA standards. You can do all these things by simply switching to high frequency opportunity chargers. A full bridge IGBT switch mechanism is utilized by the high frequency charger to produce the cleanest DC output achievable from an industrial battery charger today. Your overall operating costs will go down by this excellent switching mode circuitry which gives you with the best of both worlds: lessened costs and onward productivity. Read more >>

03

Oct

El crecimiento de los transistores de potencia regresa después de un período volátil, según IC Insights