20

Sep

For locomotives, which are driven by diesel or electricity, EMU and DEMU vehicles with AC Traction Motors, new microprocessor based AC-AC Traction System (MAS) offers the latest in technology combining IGBT based Traction Converter with DSP and microprocessor based embedded controls. Microprocessor based Locomotive Control system is used in conjunction with IGBT based traction converter to implement this solution.

Every traction converter can be configured to have single or multiple inverters. Each Inverter can be further configured to drive single traction motor (independent axle control) or multiple traction motors (bogie control). Existing product offering ranges from 650kW per Inverter for bogie control to 550kW per Inverter for independent axle control. Anywhere between 2 to 6 such inverters are packaged into one traction converter depending on application with total power rating in the range of 1.3MW to 3MW. Last solution can be scaled or optimized for specific application requirement.

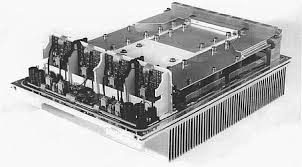

Typically heat pipe depended heat sinks are used with forced air cooling to cool down the IGBT switching devices. Both on-board as well as under frame options are available depending on space, weight constraints and cooling air availability. The blowers for cooling air are controllable at different speeds or can be turned off depending on heat sink temperatures, so as to enhance the blower life.